From the WSJ:

Companies were quick to lay off workers, idle`factories and sell unprofitable businesses during the recession. In April, U.S. manufacturers were operating at just 70.1% of their potential capacity, up from a low of 65.1% last June, but well below their historical average of 80.8%.Getting capacity back up and running isn't easy. Rehired employees who have been out of work a year or more typically need some retraining. Production equipment may also need to be recalibrated and tested.

Here's a hypothetical to show the difficulties raised. Company X sees an increase in demand. However, because this new increase will boost capacity, there are difficult questions to ask.

1.) Is this a temporary boost in orders? Is it only from one customer or a group of customers? Is this a one-time order boost, or is there an increase in demand from the customer's end?

2.) What does the owner of the company see for the economy?

Ms. Zierick says that one of her best customers called earlier this year with a rush order for a custom circuit-board component. She says she didn't want to restart a second shift, not only because it would mean higher utility and administration costs, but also because she expects the economy to slip back into recession.

If you think the economy is going to slip back into a recession, you won't be motivated to add to your work force.

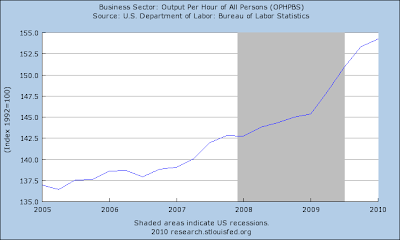

3.) Consider this chart of output per hour from the St. Louis Federal Reserve:

That charts says you can do more with less. In other words, why hire someone when you can get the same number of people to increase their productivity?

4.) Uncertainty. There have been some big changes in Washington over the last year. Uncertainty can lead business to not do anything while they figure out what the changes mean.

While manufacturing is increasing production, there are lots reasons holding people back from hiring new employees right now.